Raytac Corporation

Bluetooth module maker based on Nordic nRF51 & nRF52 solution

(Nordic nRF51822 & nRF51422 & nRF52832 & nRF51802)

Bluetooth Specification Version: BT4.0 & BT4.1 & BT4.2 & BT5

Tel: +886.2.3234.0208

email: service@raytac.com

Raytac Corporation

Bluetooth module maker based on Nordic nRF51 & nRF52 solution

(Nordic nRF51822 & nRF51422 & nRF52832 & nRF51802)

Bluetooth Specification Version: BT4.0 & BT4.1 & BT4.2 & BT5

Tel: +886.2.3234.0208

email: service@raytac.com

Raytac Corporation

A BT4.1 & BT4.2 module maker based on Nordic nRF51 & nRF52 solution

(nRF51822 & nRF51422 & nRF52832 & nRF51802)

Tel: +886.2.3234.0208

email: service@raytac.com

Mesh Network is future of IoT, also an issue that raised most interests among developers.

With the official Bluetooth Mesh nearing release by SIG, Nordic offers nRF Connect Mesh to provide a solid tools for developers to create mesh-enabled projects.

For more detail, pls click below link

Developers also can access the sample code from below link

Raytac Corporation

A BT4.1 & BT4.2 module maker based on Nordic nRF51 & nRF52 solution

(nRF51822 & nRF51422 & nRF52832 & nRF51802)

Tel: +886.2.3234.0208

email: service@raytac.com

http://raytaccorp.blogspot.jp/2016/11/nordic-nrf52-module-product-line-up.html

MDBT42Q&MDBT42Q-P Spec Sheet (nRF52832)

http://www.raytac.com/download/MDBT42/MDBT42Q-Version%20B.pdf

MDBT42Q&MDBT42Q-P footprint (Pls change the footprint file name from .li to .lib to open it)

https://mega.nz/#!ElhDCA4I!Dp-gsXhyPhfAx0dcOseNXdPzOWYJz0XTlrEH3ZCXWgg

Will be available by middle of Nov. 2016

Will be available by Jan. 2017

Raytac Corporation

Here we provide easy setup way for customer reference.

Programming software: Nordic nRFgo

MBT40 Demo Board Schematic (Click picture to retrieve clear image)

MDBT42Q Demo Board Schematic(Click picture to retrieve clear image)

Raytac Corporation 勁達國際電子有限公司

A BT5.2 & BT5.1 & BT5 module maker based on Nordic nRF53 & nRF52 solution

(nRF5340 & nRF52840 & nRF52833 & nRF52832 & nRF52820 & nRF52811 & nRF52810 & nRF52805)

www.raytac.com email: service@raytac.com Tel: +886.2.3234.0208

Raytac Corporation

Raytac Corporation

A BT4.1 & BT4.2 module maker based on Nordic nRF51 & nRF52 solution

(nRF51822 & nRF51422 & nRF52832 & nRF51802)

Tel: +886.2.3234.0208

email: service@raytac.com

http://raytaccorp.blogspot.tw/2016/10/about-mdbt42q-bt42-module.html

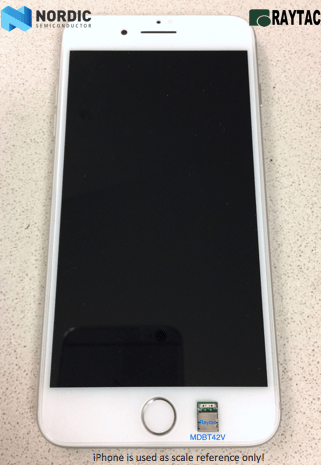

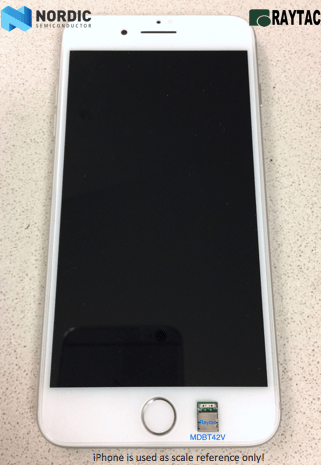

Many customers are interested in MDBT42Q based on Nordic nRF52832 solution.

Raytac’s MDBT42Q has started mass production and has widely shipped worldwide.

To provide a better service and easy customers safety regulation cost, Raytac’s remain the policy to apply module approval for most of the countries.

Allow for safety regulation requested, Raytac’s MDBT42Q has equipped the shielding case with certificate no. engraved.

Safety Regulation Approval Countries

FCC (USA): SH6MDBT42Q

IC (Canada): 8017A-MDBT42Q

Telec (Japan): 201-260496

SRRC (China): CMIIT ID: 2016DJ4571

Taiwan (NCC) : MDBT42Q (CCAM16LP1180T2) / MDBT42Q-P (CCAM16LP1181T1)

KCC (Korea): MSIP-CRM-ryt-MDBT42Q

CE (EU): R&TTE (EN300328 V1.9.1)