Bluetooth Module Maker based on Nordic nRF51 & nRF52 Solution

仕様変更(Product Change Notice : PCN)がありましたので、

当ブログにて共有します。

モジュールシールドケースにマークの表示が必要になりましたので、

KCCマークの印字を追加いたします。

その他に関しては今までと変更が有りませんので、

既にご利用頂いているお客様の方で特別手続きを行ってい頂く必要は御座いません。

参照まで。

株式会社フクミ

Bluetooth Module Maker based on Nordic nRF51 & nRF52 Solution

Raytac Corporation

A BT4.1 & BT4.2 module maker based on Nordic nRF51 & nRF52 solution

(nRF51822 & nRF51422 & nRF52832 & nRF51802)

Tel: +886.2.3234.0208

email: service@raytac.com

Mesh Network is future of IoT, also an issue that raised most interests among developers.

With the official Bluetooth Mesh nearing release by SIG, Nordic offers nRF Connect Mesh to provide a solid tools for developers to create mesh-enabled projects.

For more detail, pls click below link

Developers also can access the sample code from below link

Raytac Corporation

A BT4.1 & BT4.2 module maker based on Nordic nRF51 & nRF52 solution

(nRF51822 & nRF51422 & nRF52832 & nRF51802)

Tel: +886.2.3234.0208

email: service@raytac.com

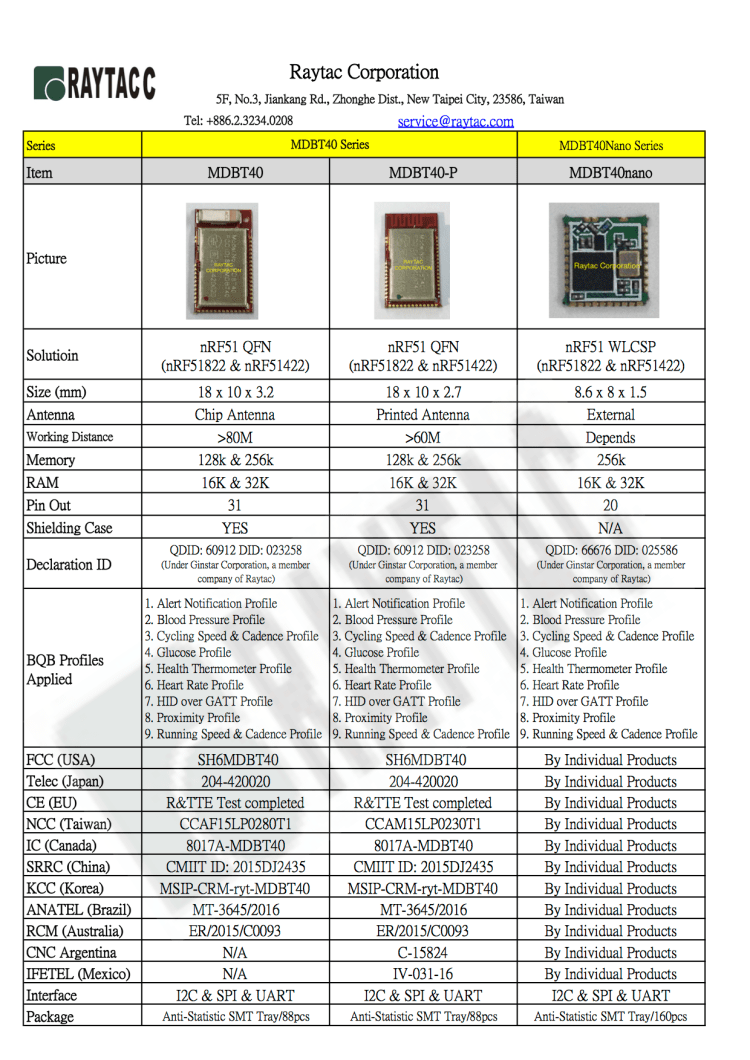

http://raytaccorp.blogspot.jp/2016/11/nordic-nrf51-module-product-line-up.html

MDBT40&MDBT40-P Spec Sheet (nRF51822)

http://www.raytac.com/download/MDBT40/MDBT40%20spec-Version%20A4.pdf

MDBT40&MDBT40-P Design & Layout Guide

(Pls change the footprint file name from .li to .lib to open it)

https://mega.nz/#!B04BmS7A!xop-1C1ynsjHXe_kDodIH8QXJn0UWtY6gZ7zHxSg8Oo

Raytac Corporation

■特徴

■特徴

Here we provide easy setup way for customer reference.

Programming software: Nordic nRFgo

MBT40 Demo Board Schematic (Click picture to retrieve clear image)

MDBT42Q Demo Board Schematic(Click picture to retrieve clear image)

Raytac Corporation 勁達國際電子有限公司

A BT5.2 & BT5.1 & BT5 module maker based on Nordic nRF53 & nRF52 solution

(nRF5340 & nRF52840 & nRF52833 & nRF52832 & nRF52820 & nRF52811 & nRF52810 & nRF52805)

www.raytac.com email: service@raytac.com Tel: +886.2.3234.0208

Raytac Corporation

Raytac Corporation

A BT4.1 & BT4.2 module maker based on Nordic nRF51 & nRF52 solution

(nRF51822 & nRF51422 & nRF52832 & nRF51802)

Tel: +886.2.3234.0208

email: service@raytac.com

http://raytaccorp.blogspot.tw/2016/10/raytacs-nrf51-module-mdbt40mdbt40-p.html

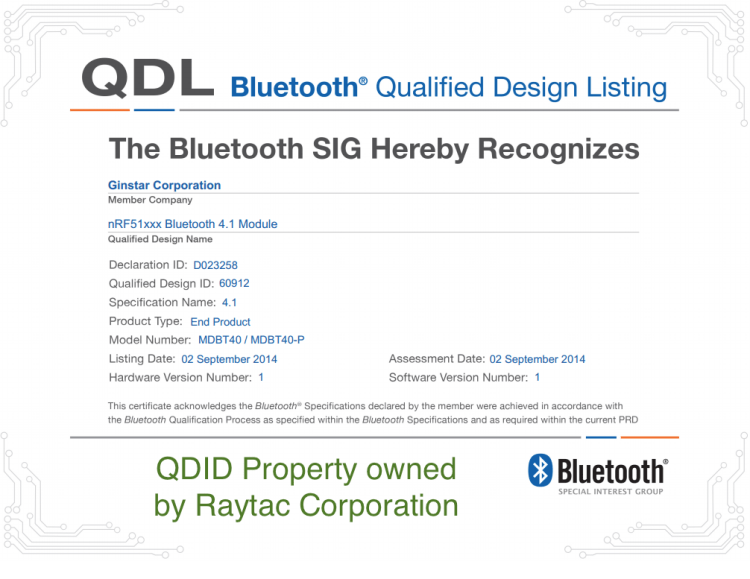

Bluetooth products must purchase DID and submit the testing evidence issued by BQE to completed the SIG registration and activate the DID

Only products’s DID been activated then allowed to use Bluetooth logo.

Developer’s who built the products based on Raytac module is allow to relable Raytac’s DID to easy the process.

Simply purchase their own DID from SIG, and relabel Raytac’s DID then can completethe Bluetooth activation process.

Raytac’s MDBT40/MDBT40-P QDID/DID is applied by subsidiary of Ginstar Corporation.

The QDID is 60912 / D023258

We welcome all Raytac’s customers to relabel the QDID as long as product built by MDBT40/MDBT40-P. As such, the Bluetooth process becomes simple and cost effective.